Originally posted on November 11, 2019, this post has been updated for accuracy and relevancy

Working in a lab involves using some pretty elaborate equipment. Here at SEPS, we’ve certified and decontaminated equipment for over 18 years. Scientists in several industries rely on their instruments to produce data and conduct their research. And one device that’s critical to several industries is the laminar flow hood.

Laminar flow hoods have a lot of similarities in common with fume hoods. Both are instruments that regulate airflow to protect samples and workers, and prevent contamination. The laminar flow hood has several different applications, from engineering delicate electronics to developing prescription medications.

Below, we’ve broken down some of the most essential information about laminar airflow and laminar flow hoods. This includes their primary purpose and what makes them so essential to the work of so many labs.

What is Laminar Airflow

The definition of laminar airflow is air moving at the same speed, and in the same direction with no crossing of streams. Uniform airflow is critical to the functioning of a laminar flow hood. The air will deposit mostly invisible particles on nearby surfaces when the airflow is not laminar.

Environments that are sensitive to particle contamination (such as cleanrooms) need laminar flow hoods to protect samples and personnel. There are two kinds of laminar flow hood designs: vertical and horizontal (more on that later). The choice between which to use depends on the lab’s requirements.

Why Use a Laminar Flow Hood

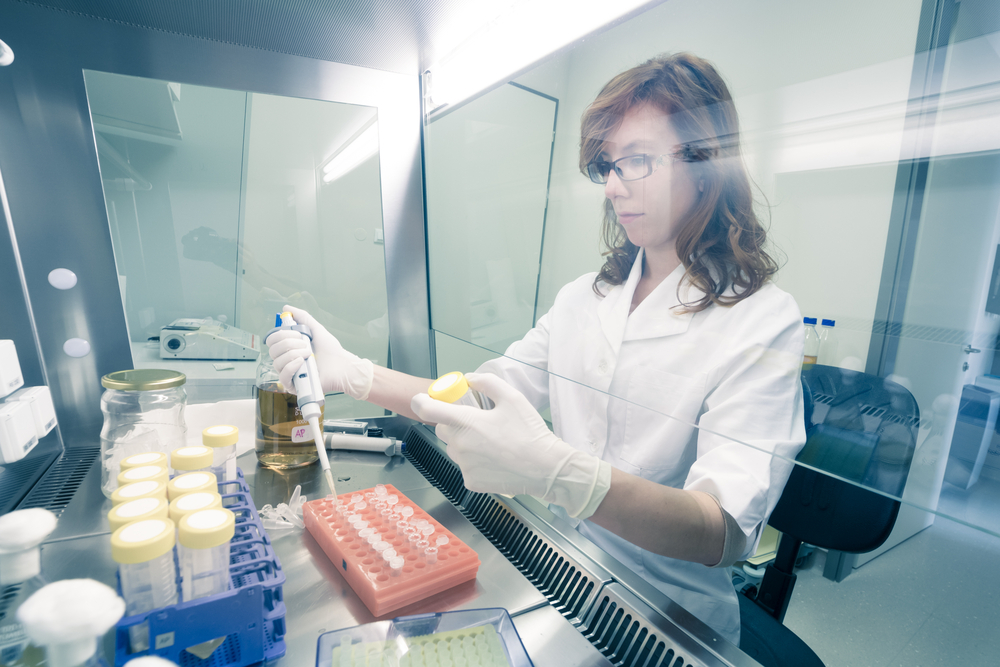

Laminar flow hoods create a work environment free of particle contamination. In the age of COVID-19, this isn’t something to be taken lightly. Industries that handle sensitive biological samples must keep the samples free of airborne contaminants. Laminar flow hoods sweep particles away from the work area.

Certain samples, whether they’re biological or electronic, must remain completely free of particles in order to complete the work successfully. Employees can unwittingly compromise them if they handle them out in the open without a laminar flow hood.

Some of the samples can be hazardous to nearby personnel, presenting a safety risk without the right equipment to direct and filter the air.

Horizontal vs Vertical Laminar Flow Hoods

There are two different kinds of laminar flow hoods: vertical and horizontal. In a vertical laminar flow hood, the filter is above the workspace and the unit directs air downward. And, in the horizontal laminar flow hood, the filter is behind the workspace and the air moves forward.

Vertical Flow Hoods

Often, labs choose vertical flow hoods because they look like much smaller versions of cleanrooms. Cleanrooms also have fans and filters installed in the ceiling to direct airflow. This means that overhead clearance should be verified before selecting one for your lab.

Vertical flow hoods reinforce the gravitational pull and sweep particles outside of the unit. Usually, they exit the hood through an access area in the front of the flow hood. Generally, most consider them more effective in protecting the lab personnel who operate it.

Horizontal Flow Hoods

Horizontal flow hoods require some additional depth in the lab in order to accommodate the fan and filter unit. With horizontal flow hoods, the fan and filter are on the back of the unit. Therefore, if there’s a limit to your space, a horizontal flow hood might not be the best choice for you.

Like vertical laminar flow hoods, the airflow does initially come from the top of the unit. However, it’s very quickly shifted downward and is processed across the workspace in a horizontal direction. The constant, filtered airflow is ideal for the preservation of samples and materials handled within the flow hood. If you plan on handling anything hazardous, a horizontal laminar flow hood is definitely not the ideal choice.

Neither a vertical nor a horizontal flow hood should be used to handle biohazards. Only approved containment systems like biosafety cabinets should be employed during processes requiring Biosafety Level 2 or 3 containment.

Both models should run for (at least) fifteen minutes before you begin working within them. Running the fan will clear any airborne particles before you use it.

Laminar Flow Hood Testing & Certification

Some of the laminar testing services include:

- Air velocity tests for contamination protection

- HEPA filter checks for leakage or contamination

- Surface testing for bacteria or fungi

- Light and sound measurement for worker comfort level

- Airflow visualization to verify the hood is providing non-turbulent airflow

Conclusion

Laminar flow hoods are just one of the many unique instruments labs use in order to control their environments and protect their work. The decontamination, repair and certification of scientific equipment are all services in which SEPS specializes.