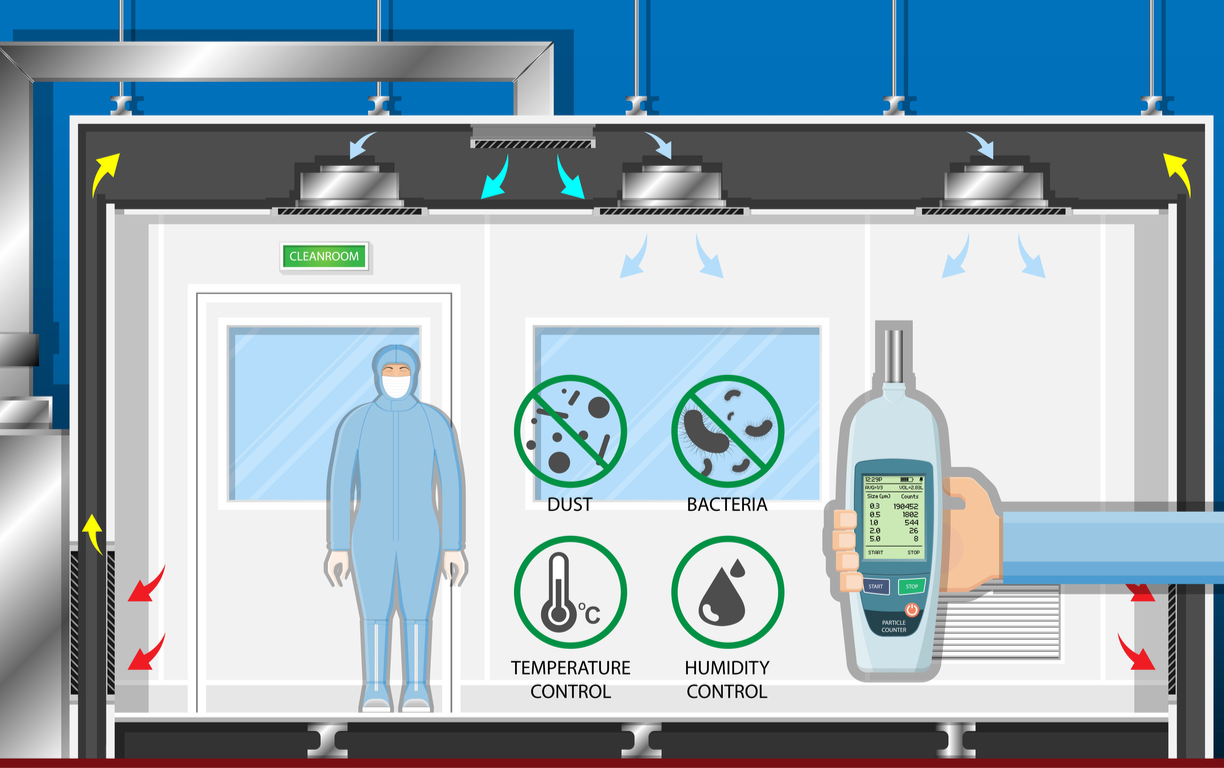

Within several scientific industries, workers must conduct research or manufacture in extremely clean, sanitary environments. Cleanrooms are the solution to this particular need. And, in critical environments, the cleanliness relies heavily on airflow.

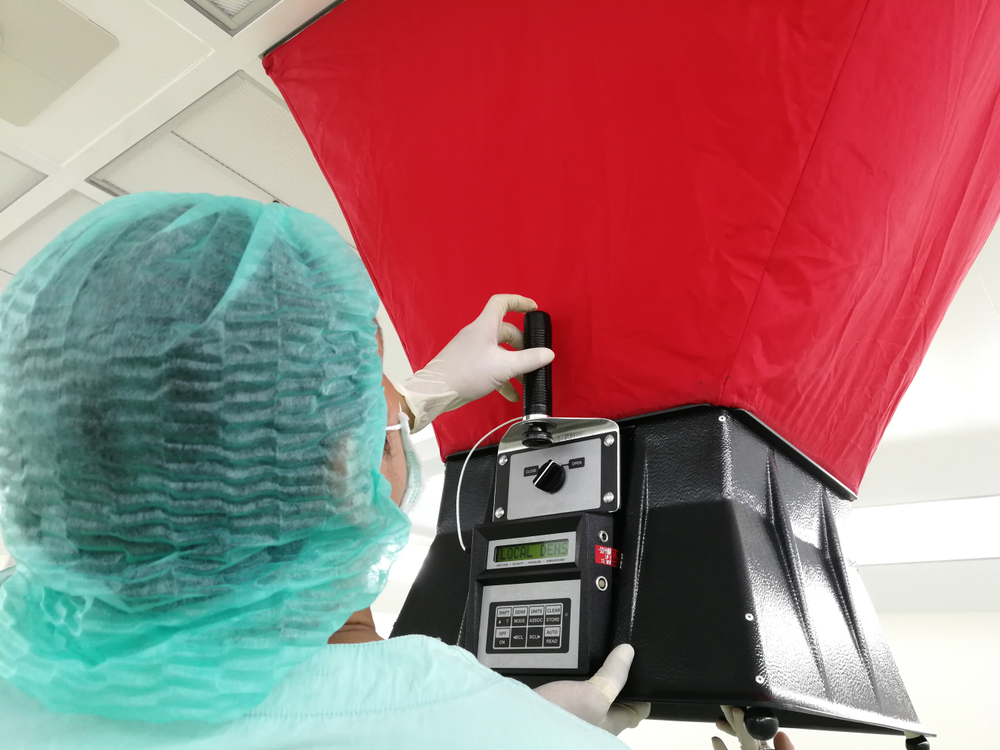

Creating and maintaining the perfect cleanroom is no easy task. They must adhere to high, rigid standards, specifically the FDA’s. In addition, every cleanroom and the equipment within must undergo consistent testing and certification.

In fact, failing to maintain uniform airflow and velocity can negate your clean environment. At SEPS, our services include testing of airflow volume, velocity testing, room air changes, and more. In this post, we’ll discuss cleanrooms and the importance of uniform airflow. Read on to find out more!.

Types of Cleanroom Airflow

Depending on your cleanliness needs and the size of your facility, you’ll need a different kind of airflow. Additionally, we recommend assessing factors like the size of your staff, quality of cleanroom attire, and the number of entries/exits.

Cleanrooms use fan and filter units to limit particles contaminating the air. Generally, cleanrooms use a HEPA filter, which stands for “highly efficient particulate air.” Of course, industry experts consider these the very best and most efficient filters available.

Laminar Air Flow

Laminar airflow means that the air traveling within the room moves in one direction. Usually, the airflow’s direction is vertical.

Cleanrooms in the ISO-1 to ISO-5 classes rely on laminar airflow. It’s the most effective in preventing contamination.

Laminar airflow hoods maintain the unidirectional airflow. In addition, the cleanroom structure contributes to keeping the airflow unidirectional.

Turbulent Airflow

Turbulent or non-unidirectional airflow is sufficient for class ISO-6 and above cleanrooms. The air won’t be regulated for direction or speed.

Swirling air allows particles to move around, rather than flow down and out like the rigorous laminar airflow system. Of course, industries that don’t need higher classes of cleanrooms find turbulent airflow a sufficient system. Moreover, pressure-controlled areas can supplement the cleanroom for specific activities.

Pressure Controlled Environments

Clean spaces can be created for performing specific tasks. These pressure controlled environments protect samples and materials, plus the workers using them. Therefore, air pressure’s an essential component of a cleanroom.

The defining characteristics of pressure is high or low. Depending on the application, you may need a positive or negative pressure workspace.

However, it’s possible to have high/low pressure vary within your facility. For instance, you may have an ISO-7 cleanroom with an ISO-4 laminar flow unit for certain operations. By assessing your lab needs, we can help determine the type of cleanroom or equipment to satisfy regulations and preserve your end-product.

Positive Pressure Cleanrooms

Positive pressure will prevent contaminated air from entering clean areas. Lower pressure air is less likely to contaminate the air, due to the cleanroom’s high pressure.

In some cases, multi-chamber cleanrooms are designed with varying pressure levels. The room that requires utmost cleanliness will receive the highest pressure. The filtered air will flow from the cleanest and most sanitary spaces to those of lesser cleanliness.

Cleanrooms that require positive pressure house industries like pharmaceutical manufacturing, or other substances for human consumption. They’re clean, highly sanitary and contaminant-free environments. Furthermore, many of these cleanrooms have air showers at their entrances and exits.

Negative Pressure Cleanrooms

A negative pressure cleanroom will extract more air than is entering, leading to a low-pressure environment. Following regulations of biosafety levels (BSL), negative pressure ensures that any hazards are controlled within the room.

In some research activities, limiting outside contamination is less important than exposing people to the sample. For this circumstance, a negative pressure room will provide safety to the personnel and surrounding area.

Conclusion

To discuss testing, certification, sterilization, or other equipment services, contact us today!