In the fast-paced world of laboratory work, safety and efficiency are non-negotiable. SEPS Services, a leading provider of cutting-edge laboratory solutions, recognizes the significance of glove boxes in ensuring the well-being of researchers and the protection of sensitive materials. In this comprehensive overview, we delve into the intricacies of glove boxes. Additionally, we shed light on the different types and their applications. Join us as we explore the world of glove boxes and unveil the secrets to transforming your workflow.

What is a Laboratory Glove Box?

Glove boxes are indispensable tools in the laboratory landscape, offering researchers the ability to handle delicate materials and shield against hazardous substances. At SEPS Services, we understand that choosing the right glove box type is crucial for enhancing safety and efficiency in laboratory operations. Let’s explore the diverse types of glove boxes and their distinct capabilities.

What are they used for?

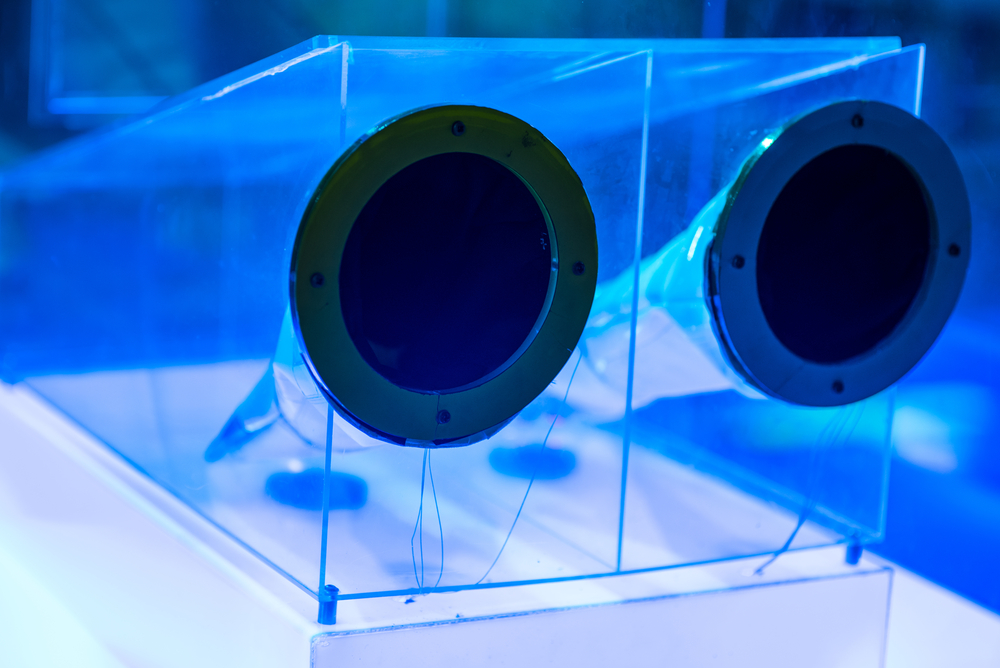

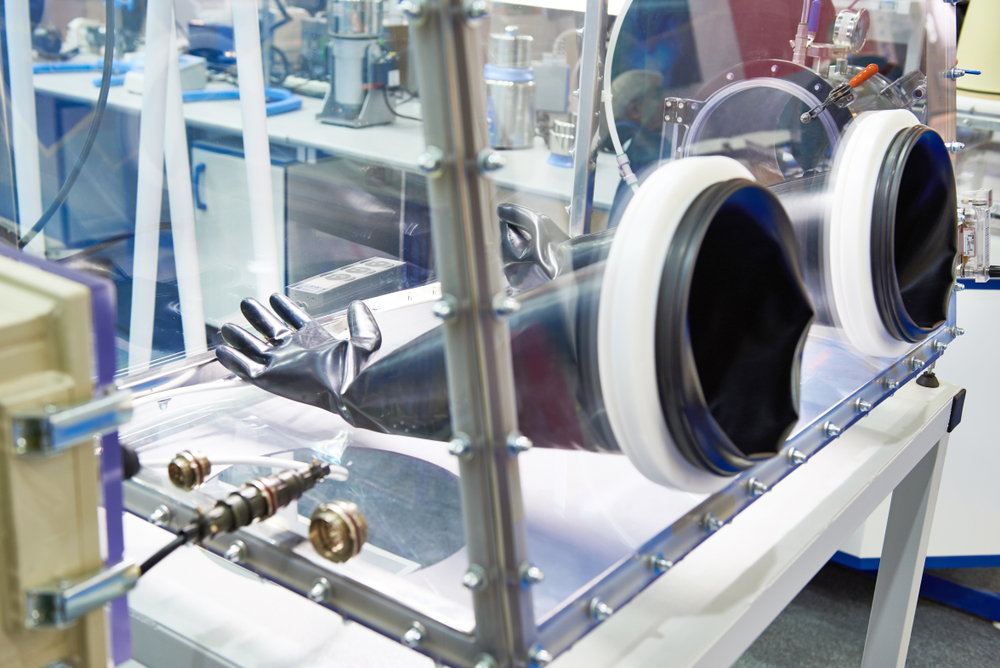

A laboratory glove box is a containment device designed to provide a controlled environment for handling hazardous materials, delicate substances, or experiments that require specific conditions. It consists of transparent walls and built-in gloves, allowing researchers to manipulate objects or perform tasks inside the box without exposing themselves to the controlled environment.

Here are some common uses and applications of laboratory glove boxes:

- Hazardous Material Handling

- Pharmaceutical Research

- Nanotechnology

- Material Science

- Electrochemistry

- Environmental Studies

- Cleanroom Applications

- Anaerobic Experiments

- Vacuum Experiments

Laboratory glove boxes play a crucial role in ensuring the safety of researchers, maintaining the integrity of experiments, and providing controlled conditions for a wide range of scientific applications.

When do you need Glove Box Testing & Certification?

The frequency of testing and certification for laboratory glove boxes depends on various factors, including the nature of the experiments conducted, regulatory requirements, and safety protocols established by the laboratory or industry standards. However, a general guideline is to perform testing and certification regularly to ensure the continued effectiveness and safety of the glove box. Typically, certification may be conducted annually or semi-annually.

The process of testing and certifying a laboratory glove box involves several steps:

-

Risk Assessment:

- Conduct a thorough risk assessment to identify potential hazards associated with the experiments performed in the glove box.

-

Regulatory Compliance Check:

- Ensure that the glove box complies with relevant safety and environmental regulations, standards, and guidelines.

-

Visual Inspection:

- Perform a visual inspection of the glove box components, including gloves, seals, windows, and filtration systems, to identify any visible signs of wear, damage, or degradation.

-

Leak Testing:

- Conduct leak testing to ensure that the glove box maintains a sealed and leak-tight environment. This may involve the use of inert gases or specialized leak detection equipment.

-

Filtration System Testing:

- Test the efficiency of the filtration system, such as HEPA or ULPA filters, to verify their capability to trap particulates and maintain a clean environment.

-

Gas Purity Testing:

- For controlled atmosphere glove boxes using inert gases, verify the purity of the gases and the effectiveness of the gas purification systems.

-

Pressure Testing:

- Test the internal pressure management system to ensure that the glove box maintains the desired pressure differentials, such as negative pressure to contain hazardous materials.

-

Functional Testing:

- Verify the proper functioning of all controls, valves, and monitoring systems within the glove box.

-

Documentation and Certification:

- Document the results of the testing and certification process. If the glove box passes all criteria, issue a certification indicating that the glove box is safe, effective, and compliant.

-

Training and User Awareness:

- Ensure that laboratory personnel using the glove box are adequately trained on its proper use and aware of safety protocols.

It’s important to note that the testing and certification process may vary based on the type of glove box, its intended applications, and the specific requirements of the laboratory or industry. Laboratories should adhere to relevant standards and guidelines and consult with certified professionals or third-party testing services to ensure thorough and accurate testing. Regular maintenance and adherence to safety protocols contribute to the ongoing reliability of the glove box.

How to Choose the Right Glove Box for Your Lab

At SEPS Services, we believe that the journey to finding the right glove box involves careful consideration of various factors. Here are some key considerations to guide you in selecting the optimal glove box for your specific application in the Northeastern United States:

-

Environmental Factors:

- Climate: Consider the local climate in the Northeast to ensure the glove box functions optimally in the given conditions.

- Exhaust Ventilation: If the laboratory deals with harmful fumes or gases, prioritize glove boxes with effective exhaust ventilation systems.

-

Application-Specific Requirements:

- Pharmaceutical Research: If your focus is on pharmaceutical research, prioritize glove boxes with HEPA or ULPA filters for stringent hazard control.

- Material Science: For material science applications, controlled atmosphere glove boxes with precise atmosphere control are essential.

-

Compliance and Certification:

- ISO Class 1 Barrier: Ensure that the glove box meets ISO Class 1 standards to guarantee a high level of protection.

What are the Different Types of Laboratory Glove Boxes?

Laboratory glove boxes come in various types, each designed to meet specific research and safety requirements. Here are different types of laboratory glove boxes:

-

Moisture Isolators and Barrier Isolators:

- Purpose: Designed to protect researchers and sensitive materials.

- Applications: Commonly used in pharmaceutical research and nanotechnology.

- Features: Equipped with high-efficiency particulate air (HEPA) or ultra-low penetration air (ULPA) filtration to create an ISO Class 1 barrier. Suitable for tasks demanding strict hazard control.

-

Controlled Atmosphere Glove Boxes (Inert Gas Glove Boxes or Dry Boxes):

- Purpose: Maintains a leak-tight controlled environment for sensitive materials.

- Applications: Ideal for material science, electrochemistry, and environmental studies.

- Features: Allows researchers to manipulate oxygen, moisture, and/or other gases. Utilizes valves connected to purified, compressed inert gas sources to create specialized environments. Ensures controlled atmosphere for specific applications.

-

Anaerobic Glove Boxes:

- Purpose: Creates an oxygen-free environment for experiments sensitive to oxygen exposure.

- Applications: Used in microbiology, cell culture, and research involving anaerobic organisms.

- Features: Maintains low oxygen levels, typically below 1%, to facilitate anaerobic processes. Equipped with gas purification systems to remove traces of oxygen.

-

Biohazard Glove Boxes:

- Purpose: Provides containment for experiments involving biohazardous materials.

- Applications: Common in microbiology, virology, and research involving infectious agents.

- Features: Ensures a secure barrier against biohazards, protecting researchers and preventing the release of hazardous materials. Often includes air filtration systems.

-

Vacuum Glove Boxes:

- Purpose: Enables experiments in a vacuum environment.

- Applications: Used in material science, surface science, and research requiring a low-pressure environment.

- Features: Maintains a controlled vacuum environment inside the glove box. Designed with specialized seals and materials to withstand vacuum conditions.

-

Temperature-Controlled Glove Boxes:

- Purpose: Maintains a specific temperature range for experiments.

- Applications: Common in material science, electronics, and research requiring precise temperature control.

- Features: Equipped with temperature control systems, often including heating and cooling elements. Ensures a stable and controlled temperature environment.

-

Multi-Chamber Glove Boxes:

- Purpose: Provides multiple chambers within a single system for diverse experiments.

- Applications: Suitable for laboratories with varied research needs.

- Features: Allows researchers to work on different experiments simultaneously in separate chambers. Each chamber may have its own set of controlled conditions.

When selecting a laboratory glove box, it’s crucial to consider the specific requirements of your research and applications to ensure optimal safety and efficiency.

Conclusion:

SEPS Services is committed to providing state-of-the-art laboratory solutions that prioritize safety and efficiency. Understanding the intricacies of glove boxes is key to transforming your laboratory workflow. Whether you are involved in pharmaceutical research, material science, or environmental studies in the Northeastern United States, SEPS Services has the right glove box solution for you. Choose safety, choose efficiency – choose SEPS Services for your laboratory needs.