In the dynamic landscape of healthcare, precision and reliability are paramount, especially in the field of oncology compounding. At the heart of this intricate process lies the need for state-of-the-art equipment. This type of equipment ensures the safe and effective preparation of personalized medications for cancer patients. Long Island-based SEPS Services stands as a beacon of excellence, providing comprehensive lab testing, certification, and repair services for controlled environment equipment in New York, New Jersey, Connecticut, Massachusetts, and Rhode Island.

When it comes to oncology compounding, precision is not just a goal – it’s a critical necessity. The seamless operation of a compounding facility is contingent on various factors. Specialized equipment and technology are at the forefront. Here, we delve into the reasons why an oncology compounding facility may need technical support or repair services to ensure optimal performance and, ultimately, the delivery of high-quality, personalized medications to cancer patients.

1. Equipment Maintenance and Repair:

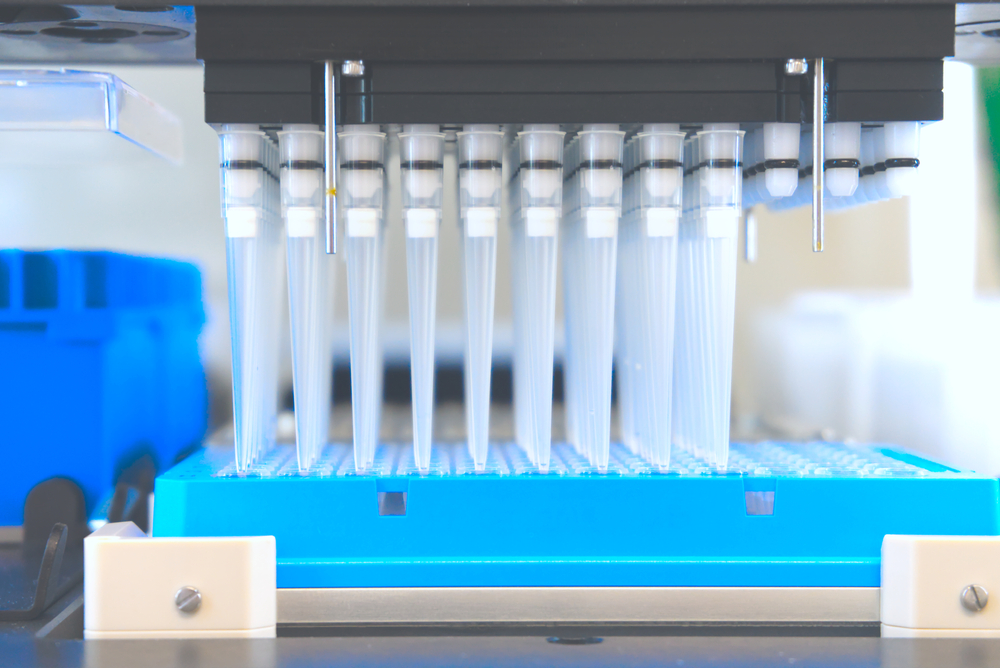

Compounding facilities rely on a spectrum of specialized equipment, including compounding hoods, mixing machines, and analytical instruments. Regular maintenance and prompt repair services are indispensable to keep these machines functioning accurately and safely, ensuring a reliable foundation for the compounding process.

2. Sterile Compounding Technology:

Oncology compounding often demands working within sterile environments. Technology such as laminar flow hoods and isolators support these demands. Furthermore, they require regular checks, calibration, and repairs to maintain the stringent sterility levels necessary for the safe preparation of medications.

3. Automation Systems:

Some compounding processes leverage automation systems for precise measurements and mixing. Technical support becomes essential to address any issues with these systems, guaranteeing accuracy in medication preparation and contributing to the efficiency of the compounding workflow.

4. Quality Control Instruments:

Maintaining high standards in medication preparation is a priority for oncology compounding facilities. Regular calibration and maintenance of quality control instruments are imperative to ensure accurate testing. Additionally, it ensures adherence to the stringent quality standards that govern the compounding process.

5. Temperature and Environmental Controls:

Certain medications necessitate specific temperature and environmental conditions during compounding and storage. Technical support is crucial to monitor and control these conditions, meeting regulatory requirements and ensuring the stability of medications throughout the compounding process.

6. Safety Systems:

The safety of both workers and patients is paramount in an oncology compounding facility. A reliable tech or repair service is needed to maintain safety systems, including ventilation systems, alarms, and emergency response equipment, contributing to a secure working environment.

Regional Excellence: Proudly Serving the Northeast

Oncology Compounding and Technical Repair Services

SEPS Services, based on Long Island, extends its expertise across New York, New Jersey, Connecticut, Massachusetts, and Rhode Island. The company’s commitment to excellence and regional accessibility positions them as a trusted partner for oncology compounding facilities in the Northeast. Furthermore, choosing SEPS means partnering with a regional leader dedicated to elevating the performance of your oncology compounding facility.

Unraveling Complexities: Addressing Unique Challenges in the Northeast

The Northeastern region of the United States, encompassing states like New York, New Jersey, Connecticut, Massachusetts, and Rhode Island, boasts a vibrant healthcare landscape. Additionally, oncology compounding facilities operating in this dynamic environment face unique challenges. This includes everything from stringent regulations to diverse patient populations. Technical repair services play a pivotal role in navigating these complexities. Therefore, SEPS offers tailored solutions to ensure the seamless operation of compounding processes.

Regulatory Adherence: Navigating Compliance in a Varied Landscape

Each state in the Northeast has its regulatory framework for healthcare facilities, including oncology compounding centers. Technical repair services specializing in the region understand the nuances of compliance, helping facilities stay abreast of state-specific requirements and maintain adherence to the highest standards. SEPS’ regional expertise is invaluable in mitigating regulatory risks and ensuring a smooth workflow.

Climate Considerations: Temperature Control for Medication Stability

The Northeast experiences diverse climates, from the cold winters to the humid summers. New York-based SEPS understands the impact of these environmental factors on medication stability during compounding and storage. Furthermore, our expertise ensures that temperature and environmental controls are finely tuned to meet regulatory requirements, guaranteeing the efficacy and safety of compounded medications.

Conclusion:

Having a reliable technical support or repair service in place is not just a practical choice—it’s imperative for oncology compounding facilities. The seamless operation, regulatory compliance, and delivery of high-quality, personalized medications to cancer patients hinge on the expertise of technical support teams. By prioritizing regular maintenance, quick issue resolution, and staying abreast of technological advancements, these facilities ensure the overall safety and effectiveness of their compounding processes.