Most lab managers would agree: maintaining a lab or cleanroom is a balancing act. Labs of any kind – whether medical, biological or pharmaceutical – require constant oversight to ensure they function safely and efficiently. One of the most integral ways to ensure safety, accuracy and functionality is with lab equipment certification.

Lab certification services are essential to safety and research. SEPS professionals perform a multitude of tests to verify lab equipment performance and accuracy prior to certification. Our numerous accreditation and affiliations are a testament to our considerable expertise.

If your lab relies on a biosafety cabinet (BSC), fume hood or laminar flow unit, then certification is absolutely critical. Below, we’ve assembled the most notable benefits to scheduling routine certification.

1. Customer Satisfaction

Of course, when it comes to certain labs, research results are fundamental to their work. For example, medical labs are responsible for the collection and analysis of their clients’ biological materials. Usually, the data they collect from these materials dictate potential diagnoses of illnesses or infections. Therefore, clients expect accurate and reliable results. In the medical field, providing patients with questionable or incorrect data is simply unacceptable. In fact, it could prove to be a very reckless threat to their health.

By scheduling certification for your cleanroom or equipment, situations like this can be avoided. Certification is vital to serving your clients. Additionally, it shows your strong commitment to their health and satisfaction.

2. Quality Assurance

Essentially, lab equipment that regularly receives certification functions at their highest levels. It means that a professional expert has inspected the device and performed industry-standard tests to make sure it’s working right. Naturally, this is confirmation that the unit is delivering accurate results.

If your lab must perform research and gather data, then certification is an indisputable necessity. Without it, there’s a chance that your work can be compromised. Lab personnel could possibly distribute inaccurate results without even knowing. Equipment can be operating deficiently.

If your lab doesn’t schedule routine certification, it can be operating below the proper standards. Therefore, the quality of the work can suffer significantly. Inevitably, this means unnecessary expenses and damage to your lab’s reputation.

3. Lab Safety

Naturally, when it comes to lab work, safety should always be your highest priority. As mentioned earlier, the safety of patients can be seriously compromised without regular certification. In fields like medicine, no lab can afford to operate without it. However, in any scientific field, you can put your employees’ safety at risk without certification.

Basically, if lab personnel operate equipment that hasn’t been certified, it can be very dangerous. Dysfunctional machinery can backfire or combust in spontaneous, unpredictable ways. Consequently, this can be extremely hazardous to anyone nearby. Of course, in any lab with a biosafety rating, this is especially dangerous.

No lab can afford to go without scientific equipment certification. It can pose significant hazards to patients, clients and personnel.

4. Cost-Efficiency

Obviously, quality, safety and customer satisfaction are fantastic incentives to certify your equipment. However, another tremendous asset is saving money! No lab can be reckless with their budget. And this is a fantastic way to save money and prevent potential future losses.

Basically, if your lab’s equipment continues to operate without proper testing or calibration, it can abruptly fall into disrepair. Consequently, you’ll be responsible for repairing or replacing it. Obviously, this usually happens at the most inconvenient times. Certification is critical to the maintenance of lab equipment. Naturally, without it, your lab can run into serious, unnecessary expenses.

5. Regulatory Compliance

In addition to ensuring accurate results and safe operations, equipment certification is also a legal and regulatory necessity. Most laboratories in New York must comply with standards set by agencies like the CDC, FDA, and OSHA, as well as international organizations such as ISO and NSF. Certification helps your facility meet these requirements and avoid costly penalties or failed inspections.

Cleanroom certification, for instance, must meet ISO 14644 standards, while biological safety cabinets follow NSF/ANSI 49 testing criteria. These verifications ensure that air flow, containment, and filtration systems meet specific safety and performance benchmarks. By keeping your lab in full compliance, you not only safeguard your operations but also reinforce your credibility with partners and clients.

6. Preventing Contamination and Cross-Exposure

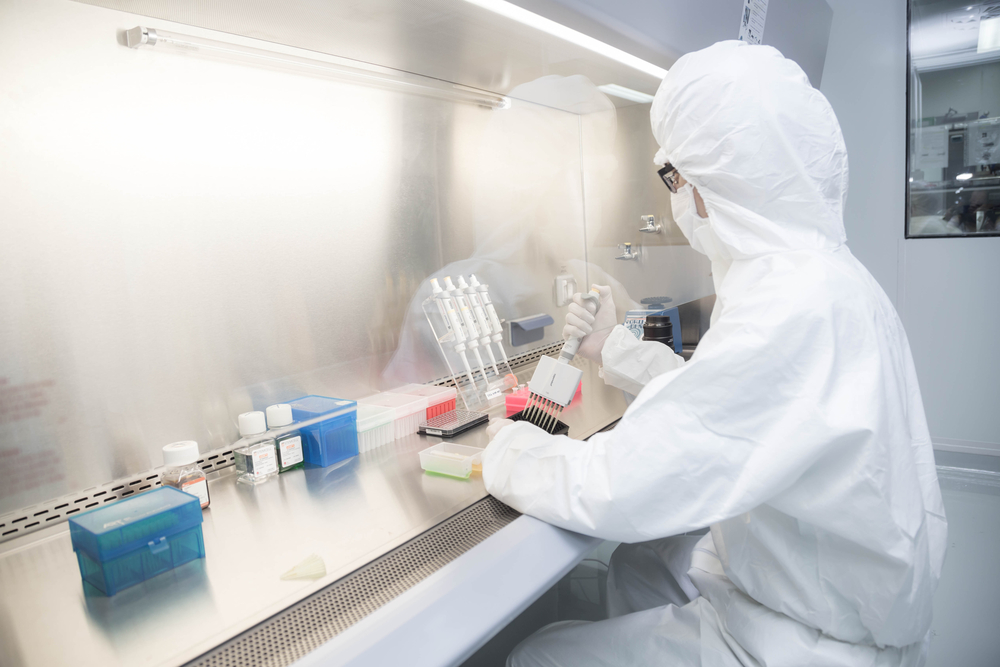

In any controlled environment, contamination is a constant risk. From dust particles to microbial matter, even the smallest impurities can ruin an entire batch of research or production. Certified equipment minimizes the chances of this happening. Testing airflow, filter integrity, and environmental controls helps identify and fix problems before they escalate into contamination incidents.

Labs that work with biological materials or pharmaceuticals must especially be vigilant. A biosafety cabinet that hasn’t been properly certified could leak airborne contaminants or fail to maintain a sterile workspace. Certification ensures that every device is functioning as intended and maintaining the necessary barrier between samples and personnel.

7. Extended Equipment Lifespan

Routine testing and certification also prolong the lifespan of your equipment. By catching performance deviations early, you can schedule timely repairs and avoid catastrophic breakdowns. Think of certification as preventative care—it keeps your tools in top shape, just like regular health checkups keep people healthy.

Whether you operate a fume hood, laminar flow hood, or autoclave, small performance issues can lead to bigger mechanical failures over time. Certification not only helps you identify wear and tear but also ensures that calibration remains precise, leading to more years of reliable performance.

8. The Certification Process Explained

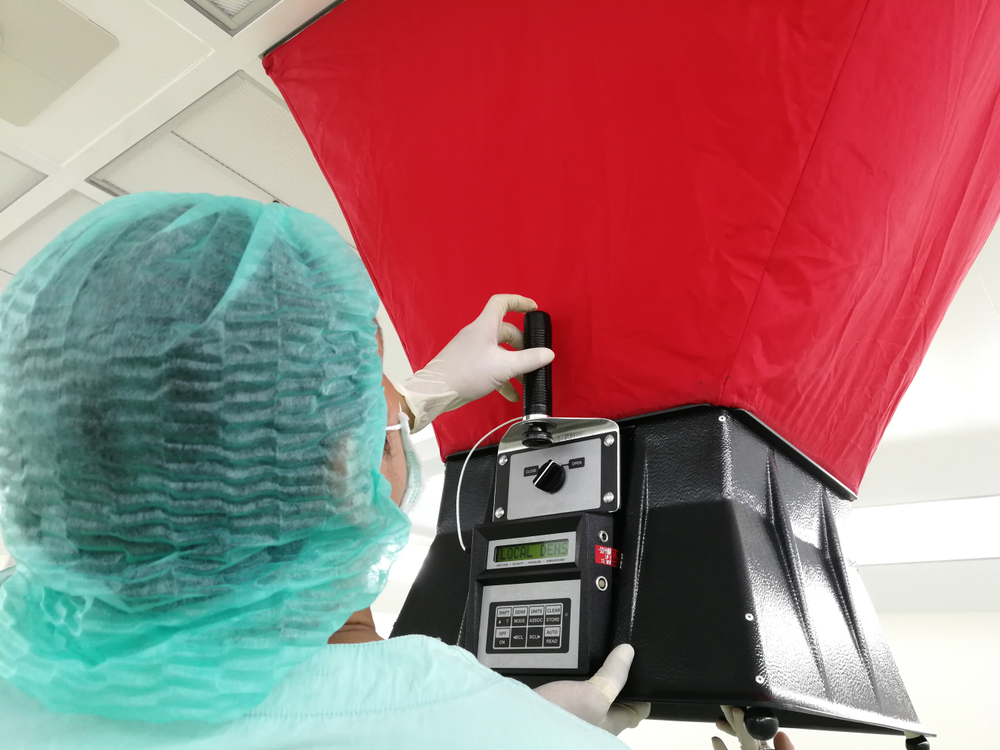

So, what happens during a lab equipment certification? At SEPS, our technicians follow a thorough, step-by-step process that aligns with industry standards. Each piece of equipment undergoes a detailed inspection and testing phase. Airflow velocity, HEPA filter integrity, light levels, sound measurements, and vibration tests are all assessed.

Once testing is complete, technicians provide a comprehensive report detailing all findings. If adjustments or repairs are needed, they’re completed promptly to bring equipment back into compliance. The final stage includes a detailed certificate documenting all test results—providing your lab with a record of compliance and proof of operational integrity.

9. Common Equipment That Requires Certification

While most lab environments share similar safety goals, the equipment requiring certification can vary widely. Some of the most commonly certified lab equipment includes:

- Biological Safety Cabinets (BSCs)

- Laminar Flow Hoods

- Fume Hoods

- Cleanrooms and Controlled Environments

- Autoclaves and Sterilizers

- Incubators and Refrigeration Units

- Airflow and Filtration Systems

Each type of equipment plays a vital role in maintaining the precision, cleanliness, and safety of your laboratory environment. Certification ensures these systems are performing correctly according to both manufacturer specifications and regulatory standards.

10. How Often Should Labs Schedule Certification?

The frequency of certification depends on your equipment type and industry regulations. Most laboratories schedule testing and certification on an annual basis. However, high-risk environments or labs that handle infectious materials may require semi-annual or even quarterly certifications. If your facility undergoes renovations or equipment relocation, certification is also necessary before resuming operations.

Routine certification helps your team identify gradual performance changes that might not be noticeable day to day. This proactive approach helps prevent unexpected downtime and ensures that every aspect of your lab continues running at peak efficiency.

11. Partnering with Experienced Professionals

When choosing a company for equipment testing and certification, experience and accreditation matter. SEPS has been a trusted partner for laboratory facilities across New York for decades. Our technicians are trained to meet strict regulatory standards and use calibrated instruments to deliver accurate, repeatable results.

We understand that each facility has unique needs depending on its research type, equipment, and environmental requirements. That’s why we offer tailored certification programs for pharmaceutical labs, biotechnology companies, hospitals, universities, and cleanroom environments. Our goal is to help you maintain confidence in your results and compliance with all industry standards.

Conclusion

When we test and certify equipment, it’s a steadfast guarantee that it’s operating perfectly. We provide all facilities with comprehensive documents verifying the results of the tests.

At SEPS, we specialize in services that help to keep labs running smoothly. Whether it’s decontamination, biosafety cabinet maintenance or equipment calibration, they’re all very necessary ways to keep personnel safe, quality consistent and equipment intact.

Schedule Your Next Certification Today

If your laboratory is due for testing or certification, don’t wait until a problem arises. Regular certification keeps your facility compliant, efficient, and safe for everyone involved. Contact SEPS today to schedule your next service and experience the peace of mind that comes from working with New York’s trusted lab certification experts.

Frequently Asked Questions About Lab Equipment Certification

How often should my lab equipment be certified?

Most lab equipment should be certified at least once a year. However, depending on your lab’s classification, safety requirements, or the type of equipment in use, semi-annual or quarterly certifications may be recommended. Any major maintenance, relocation, or contamination event should also trigger a new certification.

What standards does SEPS follow during certification?

Our team follows leading industry standards, including ISO 14644 for cleanrooms, NSF/ANSI 49 for biological safety cabinets, and ASHRAE 110 for fume hoods. We also ensure compliance with CDC, FDA, and OSHA requirements, providing your facility with full documentation for regulatory inspections.

Does certification include equipment calibration?

Yes. During certification, we assess your equipment’s performance against calibration benchmarks. We ensure instruments are accurately measuring airflow, pressure, temperature, and other key parameters. If calibration is needed, we can perform it during the same visit for convenience.

What happens if my equipment fails certification?

If any piece of equipment fails certification testing, SEPS provides a full diagnostic report outlining the issue and recommended corrective actions. Our technicians can perform most repairs or adjustments on-site and retest immediately to restore compliance.

Is lab equipment certification mandatory in New York?

While not every type of lab equipment is regulated by law, most facilities in New York are required to maintain certification to comply with safety and quality standards—especially medical, pharmaceutical, and research labs. Certification helps ensure compliance with OSHA, ISO, and state health department requirements.

How long does certification take?

The duration depends on the number of devices being tested and the size of the facility. A typical certification appointment for several pieces of equipment may take a few hours. Larger cleanrooms or multiple units may require a full day or more for comprehensive testing and reporting.

Can certification improve lab productivity?

Absolutely. When your equipment is operating at peak efficiency, research and production processes run smoother. Certification reduces downtime, prevents contamination incidents, and ensures consistent data—leading to improved overall productivity and reliability.

Why choose SEPS for lab testing and certification?

SEPS is a trusted New York-based provider with extensive industry experience and multiple accreditations. Our certified technicians deliver precise, documented results while prioritizing safety, compliance, and efficiency. We’re dedicated to helping labs maintain the highest performance and safety standards possible.